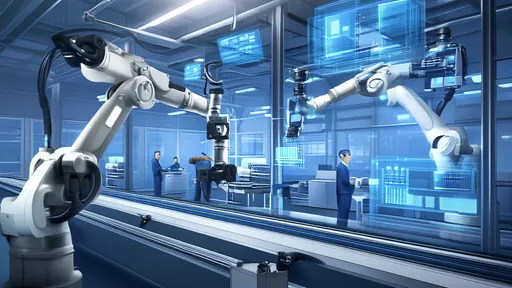

The hum of autonomous trucks gliding along highways is no longer science fiction but an emerging reality reshaping the logistics landscape. As pilot programs for self-driving trucks expand on major freight corridors across the United States and beyond, the industry stands at the precipice of a transformation promising unprecedented efficiency and cost reduction.

In recent months, several leading autonomous vehicle companies have launched extended test operations on interstate routes, with trucks often running between distribution hubs in Sun Belt states where weather conditions are favorable. These aren’t merely proof-of-concept demonstrations; they are real-world stress tests involving payloads from major retailers and manufacturers. The early data, though closely guarded by participating firms, points to significant improvements in fuel efficiency, reduced transit times, and—most critically—a dramatic decrease in labor costs, which traditionally constitute the largest expense for freight carriers.

The potential for cost savings is staggering. Unlike human drivers, autonomous systems don’t require rest breaks, sleep, or shift changes. They can operate nearly continuously, only pausing for refueling and maintenance. This effectively compresses delivery timelines and increases asset utilization. A human-driven truck might cover 500-600 miles in a day; an autonomous counterpart could theoretically double that output. For logistics managers, this isn’t just about doing things faster—it’s about rethinking network design, inventory levels, and fulfillment strategies altogether.

Beyond labor, the efficiency gains extend to fuel consumption, a major and volatile cost center. Autonomous driving systems optimize acceleration, braking, and cruising in real-time based on traffic, topography, and weather. They maintain perfect following distances and execute hyper-efficient drafting maneuvers in platoons—where multiple trucks travel closely together to reduce aerodynamic drag. Early reports from pilots suggest fuel savings of 10% or more are achievable, a figure that translates to billions industry-wide when scaled.

However, the road to autonomy is not without its bumps. Regulatory hurdles remain a significant challenge. While the federal government has provided a framework, state-level regulations are a patchwork of differing standards and permissions. Insurance models are also in flux, with liability questions shifting from human error to system reliability and cybersecurity. Public acceptance, too, is a work in progress, though the sight of driverless trucks on highways is becoming less jarring with each passing month.

The technology itself is advancing at a breakneck pace. Lidar, radar, and camera systems are becoming more sophisticated and less expensive. Machine learning algorithms are being trained on petabytes of driving data collected from these pilot programs, constantly improving their ability to handle complex scenarios like construction zones, erratic human drivers, and severe weather. Redundancy is built into every critical system to ensure safety, making these trucks, proponents argue, ultimately safer than their human-piloted counterparts.

The impact on the workforce is a topic of intense debate. While the long-term vision suggests a reduction in traditional driving jobs, the industry is simultaneously creating new, high-skilled roles in remote operations, fleet management, and data analysis. The model shifting toward a transfer hub system, where human drivers handle the first and last miles in complex urban environments, while autonomous systems dominate the long, monotonous highway stretches. This hybrid approach could redefine, rather than eliminate, the truck driver's role for years to come.

For shippers and consumers, the promise is lower costs and increased reliability. The efficiency gains from autonomous trucks could dampen the impact of fuel price spikes and driver shortages that have long plagued the industry, leading to more stable shipping rates. In an era of just-in-time manufacturing and e-commerce demands for next-day delivery, this reliability is as valuable as the cost savings themselves.

Looking ahead, the next five years will be decisive. The focus will shift from technological validation to commercial scaling and integration into existing supply chains. Partnerships between autonomous tech companies and legacy logistics firms are multiplying, signaling a collective bet on this future. The goal is no longer to ask if autonomous trucks will become commonplace, but how quickly the industry can adapt to harness their full potential.

The highway is becoming a digital corridor, and the autonomous truck is its most intelligent asset. The journey toward a more efficient, cost-effective, and resilient logistics industry is well underway, and it's picking up speed.

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025