China's technological landscape is undergoing a seismic shift as its leading AI enterprises achieve groundbreaking advancements in large-scale models, with deep integration into smart manufacturing applications reshaping industrial paradigms. These developments are not merely incremental improvements but represent fundamental leaps in how artificial intelligence interacts with and optimizes production ecosystems.

The core of this transformation lies in the sophisticated algorithms developed by companies like SenseTime, Baidu, and Alibaba Cloud. Their massive neural networks, trained on unprecedented volumes of industrial data, now demonstrate remarkable capabilities in predictive maintenance, quality control, and supply chain optimization. What sets these models apart is their ability to process multimodal data—combining visual information from production lines with sensor readings, audio inputs, and textual operational data—to form comprehensive understanding of manufacturing environments.

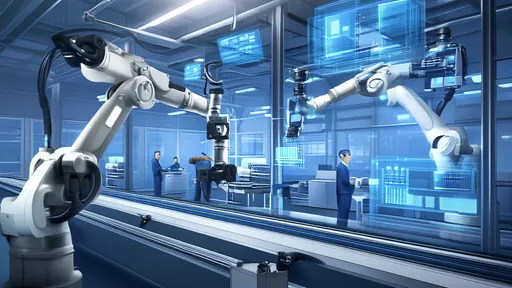

Manufacturing facilities across China's eastern industrial corridors are witnessing tangible benefits from these integrations. At a flagship electric vehicle factory in Shanghai, AI systems continuously analyze thousands of production parameters in real-time, identifying potential equipment failures before they occur. The system's predictive accuracy has reduced unplanned downtime by 47% while improving overall equipment effectiveness by nearly one-third. This isn't simply automation—it's cognitive manufacturing where machines develop situational awareness and anticipatory capabilities.

Quality assurance has been revolutionized through computer vision systems powered by these advanced models. Where human inspectors might sample products periodically, AI systems now examine every item on production lines with microscopic precision. The algorithms detect defects invisible to the human eye while continuously learning from new patterns of imperfections. This has led to remarkable quality improvements—some electronics manufacturers report defect rate reductions from 3% to under 0.2% within six months of implementation.

The integration extends beyond factory floors into entire supply networks. Large language models process global shipping data, weather patterns, and geopolitical developments to predict disruptions and optimize logistics. During recent supply chain challenges, these systems enabled manufacturers to reroute components through alternative channels weeks before human analysts recognized emerging bottlenecks. This predictive capability represents a fundamental shift from reactive to anticipatory supply chain management.

Energy optimization represents another critical application area. AI systems now manage complex industrial energy consumption patterns, balancing production schedules against energy availability and pricing fluctuations. At a major steel production facility, the implementation of AI-driven energy management has reduced power consumption by 22% while maintaining output levels. The system automatically shifts energy-intensive processes to off-peak hours and continuously optimizes furnace temperatures based on real-time production requirements.

Workforce transformation accompanies these technological changes. Rather than replacing human workers, these AI systems augment human capabilities. Factory technicians now work alongside AI assistants that provide real-time guidance through augmented reality interfaces. The systems translate complex maintenance manuals into interactive, context-aware instructions and can guide less experienced technicians through procedures that would traditionally require decades of experience. This knowledge democratization is accelerating skill development while enhancing operational safety.

Research and development cycles have dramatically accelerated through AI integration. Where new product development might previously take years, AI systems now simulate thousands of design variations, test virtual prototypes under countless conditions, and optimize materials selection based on performance requirements and cost constraints. This computational approach to R&D has compressed development timelines by 60-70% across multiple industries while improving product performance characteristics.

The underlying technological architecture enabling these advances represents significant innovation. Chinese companies have developed specialized computing infrastructure optimized for industrial AI applications. These systems combine edge computing capabilities for real-time processing with cloud-based model training, creating responsive yet increasingly intelligent manufacturing ecosystems. The hardware-software co-design approach ensures that algorithmic advances translate directly into practical industrial benefits.

Regulatory and standardization frameworks are evolving alongside these technological developments. Chinese authorities have established guidelines for AI implementation in critical manufacturing sectors, ensuring safety and reliability while encouraging innovation. These frameworks address data security, system transparency, and human oversight requirements—creating guardrails that enable rapid adoption without compromising operational integrity.

International collaboration patterns are shifting as Chinese AI capabilities mature. Rather than simply importing technology, Chinese manufacturers now export AI-powered manufacturing solutions to global markets. Partnerships with European and Southeast Asian industrial firms are creating new ecosystems where Chinese AI expertise combines with international manufacturing experience to create next-generation smart factories.

The environmental implications of these advancements are substantial. Beyond energy efficiency improvements, AI systems optimize material usage, reduce waste through better production planning, and enable circular economy models through improved tracking and recycling capabilities. These sustainability benefits are becoming significant competitive advantages as global manufacturing faces increasing environmental scrutiny.

Looking forward, the convergence of AI with other emerging technologies—particularly quantum computing and advanced robotics—promises even more profound transformations. Chinese companies are investing heavily in research that combines large language models with physical robotic systems, potentially creating manufacturing environments where AI not only optimizes processes but physically executes complex production tasks with human-like dexterity and adaptability.

The pace of change shows no signs of slowing. As computational power continues growing and algorithms become more sophisticated, the very nature of manufacturing is being redefined. What began as automation of repetitive tasks has evolved into cognitive manufacturing systems that learn, adapt, and innovate—fundamentally transforming how goods are designed, produced, and delivered to global markets.

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025

By /Sep 16, 2025